One of my goals for this model railroad is to try new technologies and techniques that can improve my modeling experience, and create a more enjoyable, authentic model railroad. On the previous layout, I initially had control panels with Rotary-switch block controls, and DPDT switches to control turnouts. When I converted the layout to DCC, I eliminated all block controls. I also decided to convert to turnout control using DCC accessory decoders. While this worked well, visitors to the layout found it difficult to remember turnout numbers, and how to throw the turnouts using the handheld throttles. A new product has been introduced, Touch Toggles from

Berrett Hill Trains. I decided to give these a try after evaluating them at a couple of train shows.

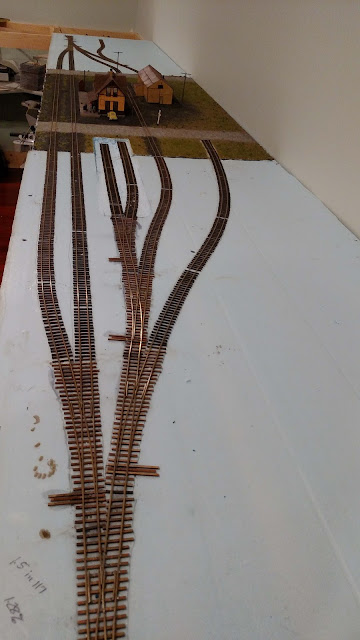

I am using Tortoise slow motion switch machines to control turnouts on the entire layout. The town of Dolores has ten turnouts, and the Lost Canon stock pens has one, for a total of eleven turnouts to be controlled by Touch Toggles. I purchased two four-output Direct System packages, each of which consist of a four-output Direct Base, four one-light Touch Toggles (which change color from red to green), and a 12-volt power supply. I also purchased two additional two-output Direct Bases, two one-light Touch Toggles, and a new Mini-Cup Toggle, to control the lone turnout in Lost Canon.

I mounted the Direct Bases to the layout framing, and connected the power supply to the 110 volt layout power. I plugged the Touch Toggles into the Direct Base, and the Tortoises are wired up to the screw connectors on the Tortoise connectors. This is much easier than soldering to the Tortoise. Note: the turnouts in Dolores are connected using SNAPS! wiring connectors from

Accu-lites. Similar connectors are available from

Berrett Hill Trains; solder-style edge connectors are available from

Greenway Products. All turnouts in the Durango portion of the layout make use of the Greenway Products edge connectors. I personally prefer a connector with screw terminals.

The Mini-Cup Toggle is intended for installations where a single control is needed, such as at the Lost Canon.

|

| These are the Touch Toggle components used on each end of Dolores. At the top is the 110 volt power supply. From left to right are the: 4-position Direct Base; 2-position Direct Base; 5 single-light Touch Toggles; Mini-Cup Toggle. Located below the Direct Base units are the #6x3/4" screws used to mount the Direct Base to the layout framework. Note that only one power supply is required. The Direct Bases can be connected together by removing the red cover from the pins, and plugging them together. |