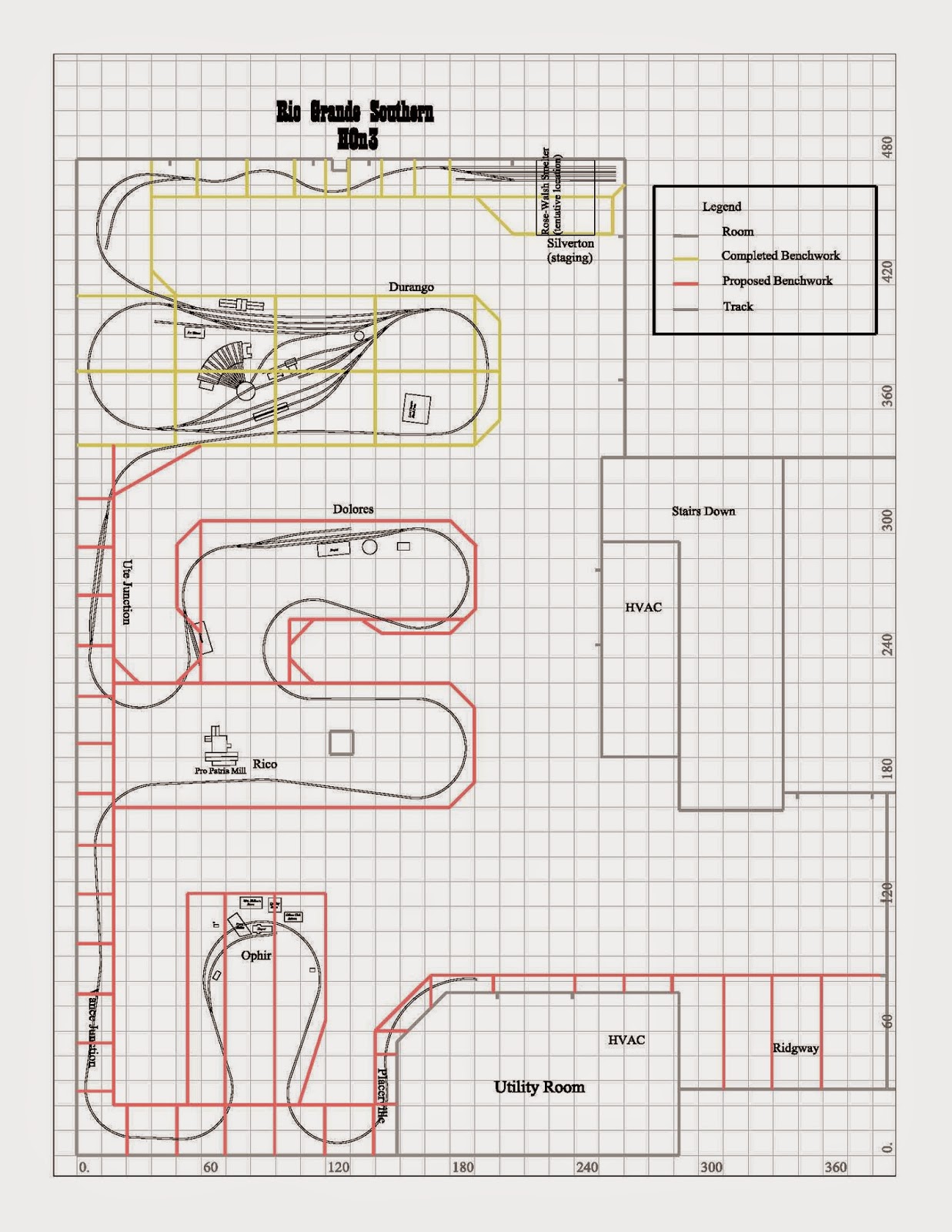

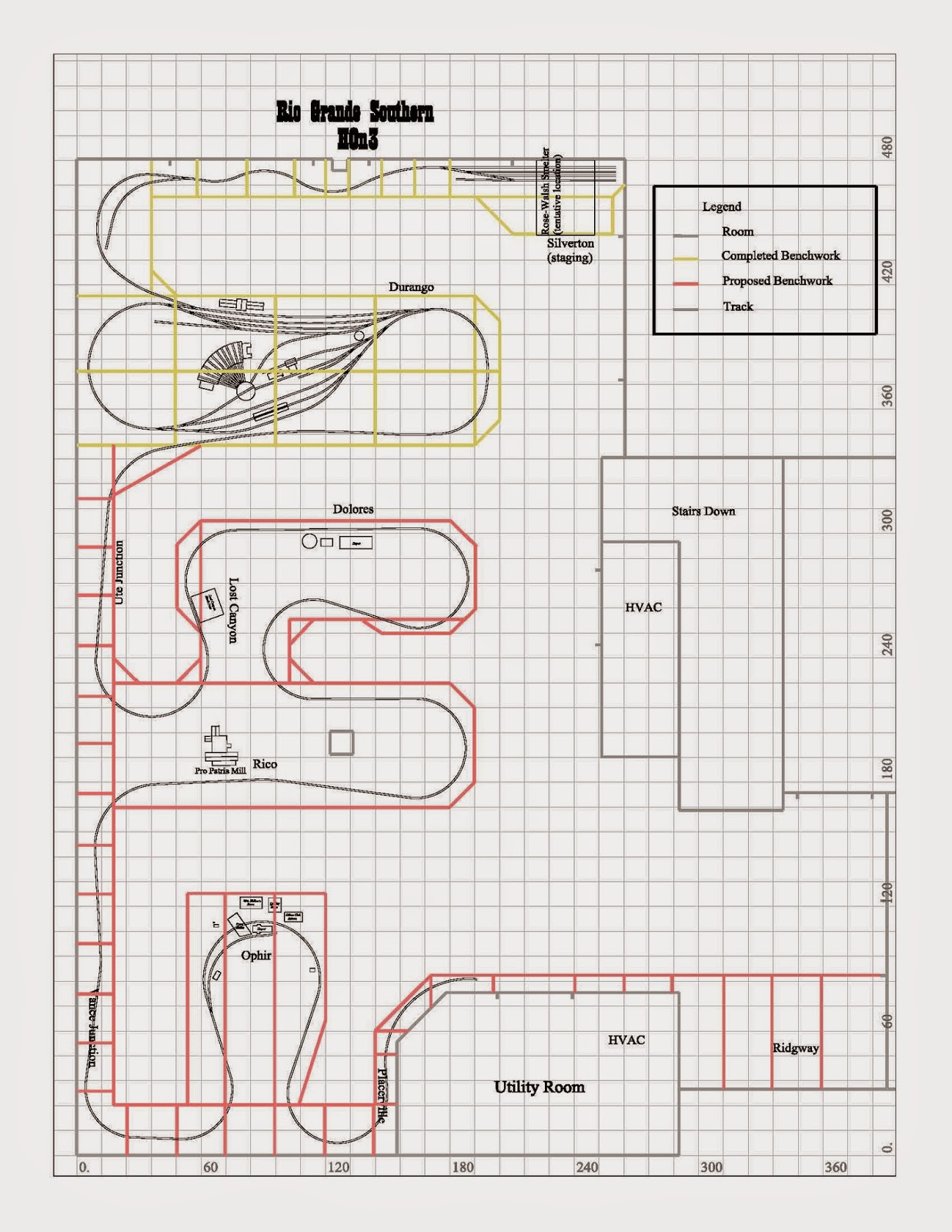

I seem to be taking a longer break from the Durango Yard than I originally anticipated. It may be a form of procrastination, because the next step is finalizing the track plan to Dolores, and then building benchwork!

Meanwhile, I have completed three more structures for my Ophir Loop portion of the layout. These were all built from

Banta ModelWorks kits: the toilet and handcar shed, and the Oilton Club Saloon.

The toilet and handcar house were painted using standard RGS colors, Jersey Cream and Brown, which are available from

PBL. These are similar to, but not the same as, the D&RGW Depot Buff and Brown. Exposed wood parts were stained using

Hunterline Creosote Black. All parts were painted or stained while still attached to the carrier sheets to effect a cleaner look. I did have a couple of minor problems with the toilet and handcar shed. The laser cut windows and doors were cut too close to the edge of the the plywood, so I had to do a bit of repairs. The handcar shed did not come with shingles, so I simply used leftover shingles from the Ophir Depot kit, and stained them with the Creosote Black. Yes, I have constructed the Ophir Depot!

The Oilton Club Saloon was stained using Hunterline Cottage White stain for the walls, Dark Green acrylic paint for the trim, and Creosote Black for exposed wood, such as the stairs. The kit includes silkspan for roofing. I cut the silkspan into four-foot wide pieces, which were installed vertically using Aleene's Original Tacky Glue. The roof was then painted with Polly Scale Grimy Black, and, when dry, weathered using Pan Pastels. The only glitch in assembling this kit was that the two short doors were not included. I was able to scatchbuild the doors from leftover plywood from the kit. The instructions made no mention of the boarded-up window, and there is no window included in the kit for that location. Photos show that this window was boarded-up at some point, so that is how I handled that window.

|

| The three new structures for Ophir Loop, from left to right, they are: the toilet, the Oilton Club Saloon, and the handcar house. |

|

| The Oilton Club Saloon, with it's boarded-up window. |

Well, back to working on the Durango Yard. I need to repair moving damage to the turntable handrails (very fragile!), and I need to attach the Roundhouse roof. However, before the roof can be attached I need to update or replace some of the microlights in the Roundhouse as some appear to have ceased working. Also, some minor (I hope!) grading work needs to be done on the track over the ashpit.